Batteries and Electronics Boards

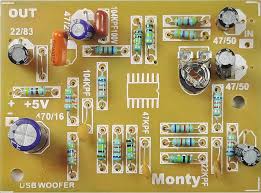

An electronics board is a circuit board that connects electronic components and transmits electricity to control them. The electrical connection is made through copper wires that form a network of pathways on the board. These pathways can be shaped, bent, or curved to fit into a space that cannot be accommodated by a traditional planar circuit board. This technology is essential for wearable electronics and other compact devices. In addition to providing power, electronics board are also used to store and protect data.

The circuit board is typically a dielectric composite material composed of an epoxy resin and a reinforcement such as a woven or nonwoven fiberglass, glass fibers, or paper. The resin provides a protective coating that shields the copper from contact with other components on the board. The composite material has a variety of different insulating values depending on the application, and can include polytetrafluoroethylene (PTFE, or Teflon), FR-4, FR-5, FR-6, GF-4, GF-5, G-10, ECB, CEM-1, or CEM-3.

Often, the conductive layers on the circuit board are formed by electroplating the copper from a metallic element such as silver or gold. These conductive paths are then soldered to the components. Depending on the type of device, the soldered connections may be made through holes in the board or through a surface mount technique. In both cases, the soldered connections are then plated with copper to make them durable and electrically connect them together.

Flexible Batteries and Electronics Boards

There are a variety of different metal materials used in flexible interconnects, each with unique properties suitable for a specific application. The choice of a material will depend on the size and shape of the interconnects, and the amount of flexibility required by the device. In general, thinner metals have better conductivity than thicker ones.

A flexible printed circuit board assembly (PCBA) for a conformal wearable battery includes attachment sections for a plurality of battery cells arranged in a grid-like pattern on a same side. The PCBA includes a plurality of cut-outs disposed along the bend axis and parallel to adjacent battery cells to reduce mechanical stresses that occur when the CWB is bent during use.

The flex PCBA has a charging connection portion that is configured to connect to one or more charging tabs on an exterior portion of the battery enclosure, and a connecting section that is configured to connect to additional circuitry on the CWB. The flex PCBA includes dog bone-shaped cut-outs 1920 disposed on the connecting portion to provide stress relief along the flex line.

The flex PCBA also has a plurality of obround-shaped cut-outs disposed on the connecting portion to reduce stress along the flex line. The obround-shaped cut-outs are sized to receive a pair of cathode and anode connection tabs, which are soldered or welded to the battery cells. The obround-shaped cut-outs also allow the charging tabs to move freely with respect to the flexible PCBA when the CWB is bent. This allows the battery cells to be connected and disconnected easily.